Petzl, a history of quality

For over thirty years, Petzl has been building its expertise in the design and manufacture of products for verticality and lighting. This adventure began with the passion for caving of an artisan, Fernand Petzl, and the need for equipment that would help Access the Inaccessible. The safety, reliability, durability, and ergonomics of products have always been the cornerstones of Petzl’s equipment creation process.

January 8 2015

Rope access and confined space

Today Petzl designs, produces and distributes millions of products across the globe, and that original standard for quality is now more essential than ever. Essential for responding to the uses they are put to, from the most basic daily ones to the most extreme. It is at the heart of the work of the company’s teams.

Design

The Petzl research department integrates all the disciplines related to the design of a product: mechanical, textile, electronic, optic and computing... Starting at the design and prototype phases, the reliability and safety of the product are continually evaluated with a strong focus on any risks to the user.

Testing

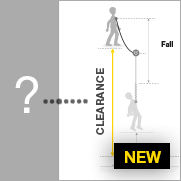

Petzl has labs dedicated to testing verticality products and headlamps. These tests often go above and beyond the required standards to help validate the reliability of products and safety for the user: dynamic fall tests, shock resistance, cycling, performance, beam quality, headlamp burn times... They are complemented by testing in the field, controlled or not, in terms of ergonomics and reliability.

Production and inspection

During manufacture, quality control is found throughout the production chain: auto-inspection of operations by machines, human inspection at key points, reinforced by error-proof systems, final individual inspection of each product.

Product guarantee

Petzl products are guaranteed for three years. In the case of a problem, Petzl’s after-sales service aims to intervene within seven working days.

To learn more, two videos

Related News