When Rope Access and Rebolting Unite

This project required the organization and logistics of a mountaineering expedition, the access skills of a climbing guide, the work positioning and rescue skills of a rope access technician, the material planning of a tower climber, the teamwork of an arborist crew, and the trade skills of fine craftsmen.

December 10 2020

The Pipe Dream in Maple Canyon is the most iconic conglomerate cave climbing in Utah. Route grades range from 5.10d to 5.14c, with a heavy skew towards the harder climbing. This is where many people find themselves projecting a route. While projecting, climbers spend a lot of time falling and working moves on one bolt repeatedly. This increases the wear on the equipment and reduces its lifetime effectiveness, even on reinforced metallic hardware. The Pipe Dream has forty routes and each route has between four and twenty bolts, with an average of about fifteen bolts and anchors. Since being developed in the late 80’s and early 90’s, the Pipe Dream has never been rebolted. Until now.

In November, the Salt Lake Climber’s Alliance took on the feat of rebolting every route in the Pipe Dream. Jesse Williams, the SLCA’s first paid Anchor Replacement Coordinator, says that the three to five person crew “replaced 239 stud/wedge and sleeve bolts with stainless steel adhesive anchors over 12 days and 451 hours.”

The SLCA decided on the Pipe Dream for several reasons: it’s a world class destination, there was a general consensus the anchors and fixed hardware were becoming less reliable, and the Pipe Dream presented a good sport climbing project because, “it’s steep and sometimes complex work and if we can do it there, we can do it about anywhere,” says Williams.

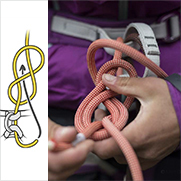

There were a few challenges of bolting in a cave besides the overhung environment. Work positioning requires being suspended on one anchor in order to install or remove another anchor. And so, once a new anchor is installed the old anchor must be removed or abandoned and patched with power tools. This means a backup rope system is always used, and sometimes additional releasable lanyards. The work progression requires primarily working from the bottom up. Each route took four progressions up the rope: aid climb to the top and install primary and backup ropes; next, ascend to locate, drill and clean new anchor holes; then, ascend again to install new adhesive anchors (while managing the epoxy cure times); last remove all old bolts and hardware, including documenting the location and gate direction of each fixed draw to assist volunteer climbers in replacing them once the work is complete.

Prior to the Pipe Dream rebolting project, Williams spent about 130 hours writing and working in the field to develop the “Best Practices for Anchor Replacement” program, which includes the “Managed Fall Protection program.” This program encompasses the qualified use of both climbing skills, industrial rope ascent/descent methods and systems to provide continuous and redundant protection for the worker: full-body harnesses, backup ropes, work seats, adjustable lanyards and releasable systems. The SLCA is leading the way for rebolting projects in the US; and the main reason for a detailed program was simple, “We want only good anchors installed, and we don’t want any of our friends and fellow climbers to get hurt. We take this responsibility seriously and hope it presents a model for climbing management that can be shared and replicated elsewhere,” says Williams.

Learn more about the SLCA Pipe Dream project.

Learn more about Petzl mobile fall arresters.

Photo Credit: Cody Kaemmerlen and Jon Vickers

Related News